The Carburetor Shop LLC

204 East 15th

Street

Eldon, Missouri 65026

Home | History | F.A.Q. | Orders | Contact Us | SELL TO US

Carburetors | Repair Kits | Other Parts | Literature | Tools | Articles | Troubleshooting | Carburetor

Identification

Passenger Kits | Truck Kits | Tractor Kits | Industrial Kits | Marine Kits | Multi-carb

set-ups

Car Comics | Car Records | Car Trading Cards | Subscription Cards | Oakland

and Pontiac

VIRTUAL

MUSEUM OF CARBURETORS

WELCOME!

The Carburetor

Shop has been acquiring unusual carburetors and related items for almost 50

years. We have enjoyed having our customers and other interested parties tour

our shop for a long time. However, thanks to new local government and

insurance regulations we are now mail order only and can no longer offer

tours of our shop, so have decided to continue to share some unusual items

with enthusiasts via the internet. It should be noted that this is not a

comprehensive history of any company, rather a sampling of carburetor

history.

ADMISSION

If you enjoy the

tour, we ask only that you share the link with someone younger than yourself.

So let's get

started! The tour is loosely arranged via carburetor manufacturing companies,

and accessory manufacturing companies. Obviously, there is some overlap.

CARBURETOR MANUFACTURING COMPANIES

Autolite | Carter | Detroit | Ensign | Holley | Kingston | Linkert | Marvel | Motorcraft | Rayfield | Rochester | Schebler | Stromberg | Tillotson

| Winfield | Zenith

Lesser known

carburetor brands

CARBURETOR ACCESSORY

MANUFACTURING COMPANIES

Ballwin-Washington | D & G | Hawk | Hygrade | Parker Brothers | Sherman | Vernay

Autolite /

Motorcraft

Autolite/Motorcraft began selling carburetors in 1957, primarily to Ford

Motor Company. A.M.C. also used Motorcraft carburetors in the late 1960's and

1970's. Autolite would place a Ford tag on carburetors purchased from Carter,

Holley, and Rochester; so many carburetors with a Motorcraft tag actually

were made by other companies

Carter

One of the older carburetor companies in the USA, Carter started selling

carburetors about 1909. While Carter sold to a number of smaller car

manufacturers in the 1910~1920 period, Chevrolet in 1923 was Carter's first

big customer. Carter was extremely successful after 1923, and by the late

1930's, according to some sources, had more than half of the carburetor

business in the USA. After Penberthy quit producing the Ball & Ball

design, Carter acquired the rights to produce this design from 1933 through

the late 1960's. Carter introduced the W series in 1931 with the W-2 used by

Nash. The W series went through the W-0, W-1, WA-1, WE, W-2 single barrel

carbs, the WD-0, WCD, and WGD two-barrel carbs, and the WCFB four-barrel

carbs. In 1950, the Y series was introduced. The Y series consisted of the

YF, YH (horizontal) and YS (sealed) single barrel carburetors. Carter also

produced the BBS (single barrel) and BBD (two barrel carburetors). In 1957,

Carter introduced the AFB 4-barrel which became one of the more successful

carburetors, both in the original equipment market and the aftermarket.

Carter produced the AFB is sizes from 400 CFM to 950 CFM. Carter also had

their "price leader" models. These would include the

afore-mentioned Ball & Ball design, the AS (late 1950's), and RBS which

superseded the AS. Carter also produced the ABD two-barrel to compete with

the Autolite 2100 for Ford vehicles, but other than Lincoln from 1959~1962,

the ABD had few buyers.

|

|

|

|

|

|

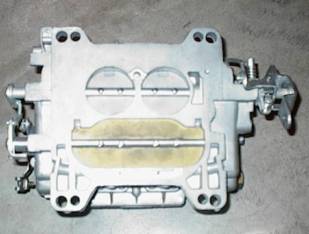

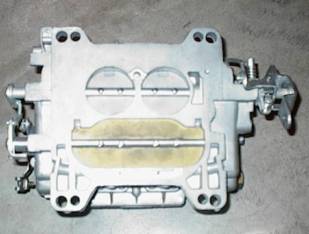

Bottom view of the Carter "trapdoor" NASCAR AFB carburetor

from 1963

|

The Carter Engineering Division prototype metering rod lathe. Features a

collet chuck, a 3450 RPM motor, and a four equally distance blade cutter

contained in the tailstock. With a skilled operator, able to cut metering

rods to the hundred-thousandth of an inch. Hand-built for Carter in 1929

when Carter began using metering rod technology.

|

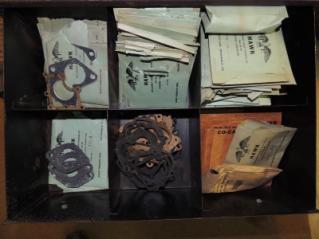

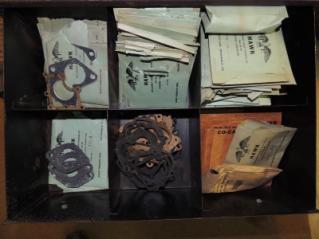

Carter aftermarket strip-kit containing several different metering rods,

metering jets, and different orifice fuel valves for performance and racing

modifications. The original group of 16 covered MOST WCFB, AFB, AVS, and TQ

carburetors. As usual, dealers starting complaining about too much

inventory, thus Carter eliminated the WCFB kits, and consolidated the AFB

and TQ kits, producing less efficient kits. The "10" series in

the styrofoam boxes, as pictured, are the more useful kits.

|

Carter offered a drill set in a foldable leather wallet to aid in

modification to calibrations.

|

|

|

|

|

|

|

1935 Carter Master Tool Kit. Carter produced tool kits in three groups:

the Master Kit for the carburetor technician that rebuilt all Carter carbs,

the Junior kit with common tools spanning all makes, and several different

dealer kits that would contain common tools for one car make, i.e. Pontiac.

|

Second generation toolbox, used from about 1946 through about 1955.

|

Third generation toolbox, used from about 1956 and newer. Note this is a

dealer kit, rather than a Master or Junior kit, so there are several empty

holes.

|

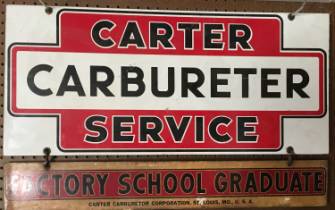

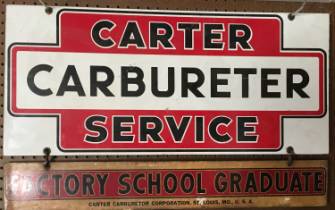

The sign could be ordered, but the Factory School Graduate addition

required graduation from the Carter carburetor school. The last instructor

was Ty Hughes, who is now teaching carburetors in a better world. He is

missed.

|

|

|

|

|

|

|

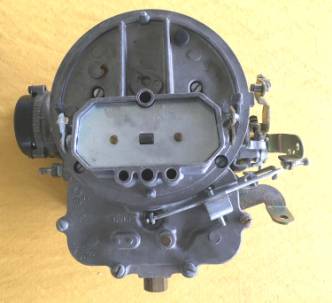

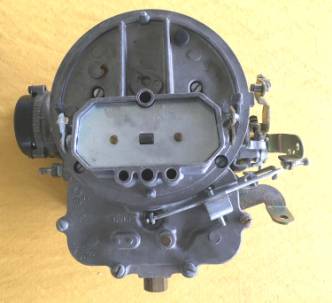

Side view of the Carter WCFB four-barrel prototype showing the

"X" (experimental) number. In alphabetic order, Carter,

Rochester, and Stromberg introduced four-barrel passenger carburetors in

1952. I will leave the argument of who was first to our visitors.

|

Top view (note bronze airhorn) of the same prototype.

|

Carter specialty cabinet containing tuning and replacement jets,

springs, fuel valves, rods, and chokes for the Carter aftermarket

performance carburetors

|

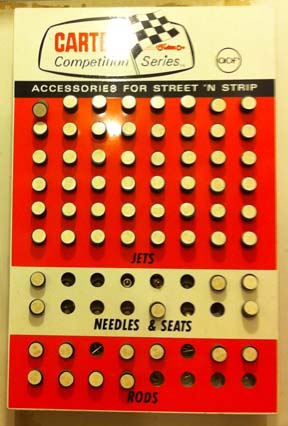

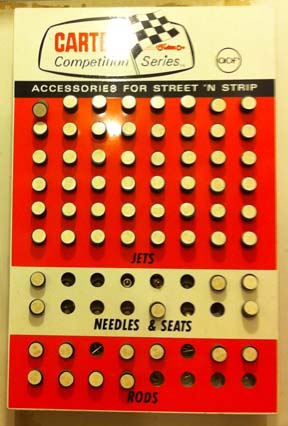

Carter specialty wall display cabinet with jets, fuel valves, and rods

for Competition Series carburetors.

|

|

|

|

|

|

|

Lighted counter-top rack to display three updraft and three downdraft

carburetors from about 1935. The glove is lighted.

|

New old stock Carter type YH number 2066s with manual choke as used on

the 1953~1954 Corvette. The choke housings were zinc diecast, and broke

often.

|

Carter WGD used as original equipment on a few 1949~1950 Oldsmobiles,

along with the infamous Rochester type AA. While scarce, these carbs are

vastly superior to the always troublesome type AA. The biggest issue facing

the enthusiast wishing to change is the availability of the special adapter

(pictured) to allow the original air cleaner to be used (no, I don't have

any extras). See the Rochester section to see the type AA.

|

Carter type ABD 2-barrel carburetor; designed to sell against the

Autolite 2100 and Holley 2300 2-barrels for Fords. Although better city

drivability and much better city fuel economy than the other two, the ABD,

with Carter metering rod technology, was more expensive. Lincoln used it

for several years, but too expensive for Fords. Carter did offer

aftermarket versions for Ford, but most buyers shopped price.

|

Detroit Lubricator

Detroit Lubricator, and a division Stewart, produced carburetors from 1913

through 1937. Some of their customers included Cadillac V-12 and V-16 engines

in the 1930's, Dodge Brothers from 1914~1928, Ford's first V-8 in 1932 and

1933, and Packard from 1905~1932.

|

|

|

|

|

|

Packard Air Valve bowl cover, proving the Packard Air Valve carburetors

were manufactured by Detroit Lubricator

|

Two views of the Detroit Lubricator type 51 used on the V-12 Cadillac. A

similar model was used on the V-16

|

|

A watch fob

|

Ensign

Ensign produced carburetors for trucks and tractors. In the 1930's, I.H.C.

acquired the rights to Ensign, and continued to use the Ensign design which

is referred to as an IHC carburetor in the INC literature.

|

|

|

|

|

|

Ensign carburetor sign. Only one I have seen.

|

|

|

|

Holley

Holley is probably the oldest well-known carburetor company in the USA.

Originally known as Holley Brothers, the first carburetors produced were a

French licensed Longuemare carburetor approximately 1901. In 1904, Holley

introduced their own design. Holley has produced carburetors for cars,

trucks, marine applications, and aircraft. Holley's biggest early customer

was probably Ford, as Ford used various Holleys, among other makes of

carburetor, on the Model T, and the later Model A. In the 1930's, Bracke,

which was listed as a division of Holley, sold a number of experimental

carburetors to Ford. These were tried, but not overly successful. Bracke also

produced carburetors for the marine trade. Another company, Chandler-Groves

sold carburetors which were marked Chandler Groves, manufactured by Holley. I

am not positive of the connection. Chandler Groves produced a single-barrel

for Packard and Plymouth; but these only lasted a couple of years. But

Chandler Groves also sold the model AA-1, which would later carry the Holley

name, and was generally known among hotrodders a the Holley 94. Holley

produce a D series carburetor, both as a single barrel and a two barrel for

the marine industry, approximate years 1929~1953. As no one at The Carburetor

Shop has an FAA license, we will not discuss the Holley aircraft carburetors,

other than to state some were produced. In the 1950's Holley tried some

unusual designs. Two and four barrel carburetors were produced with an

overhead bowl design; models 1901, 2140, and 4000. The model 4000 has been

given a number of nicknames by enthusiasts, such as "teapot"

Holleys, and "haystack" Holleys. Single barrel carbs were designed

with a bowl on the side, which decreased the height of the carburetor. The

end-bowl design was adapted to the two barrel and four barrel carburetors in

1957; the two barrel was the 2300 model, and the four barrel was the 4150

model

|

|

|

|

|

|

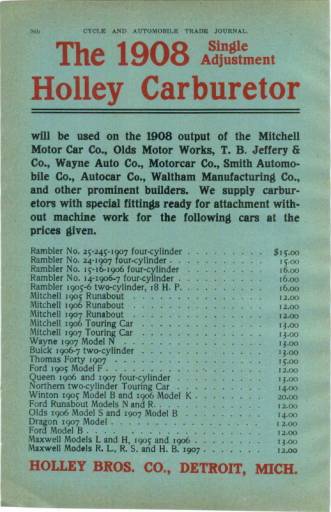

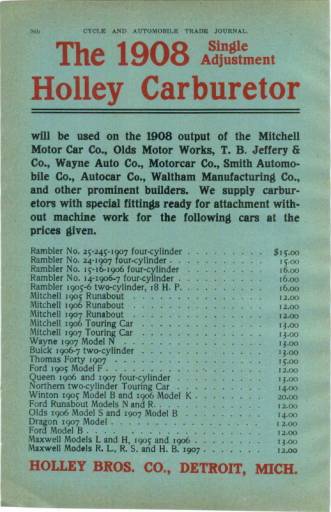

Holley Carburetor price sheet from 1908

|

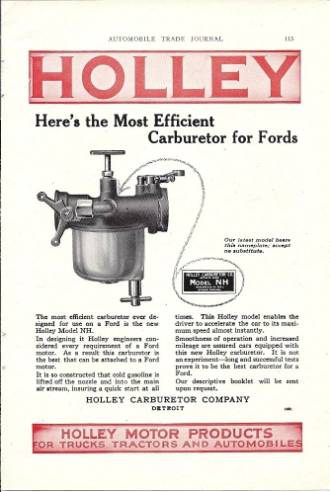

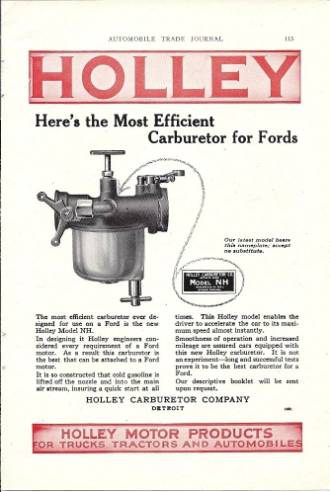

One of the more common early Holley carburetors that one will see today

|

The experimental Bracke tested on 1000 1933 Ford V-8 cars.

|

1963 Ford 3x2 set-up, with 3 Holley type 2300 2-barrel carburetors.

|

|

|

|

|

|

|

One of the Holley model 4000 "haystack Holleys". Note list

number 1074 stamped on the edge of the flange.

|

Chandler-Groves, division of Holley, parts cabinet from the late 1930's

|

|

|

Kingston

Kingston was a very popular make in the early days of the industry.

Kingston produced carburetors for cars, trucks, agricultural, industrial, and

marine engines. The earliest record in our files of Kingston is 1903, and

they continued to produce carburetors at least through the late 1930's.

|

|

|

|

|

|

Kingston original equipment carburetor used on the 1903-1904 Ford

|

Kingston original equipment carburetor for 1904 Oldsmobile

|

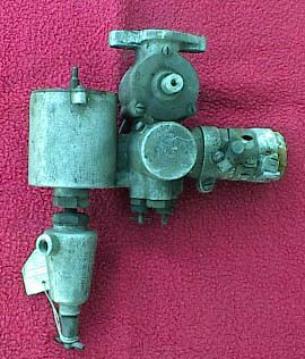

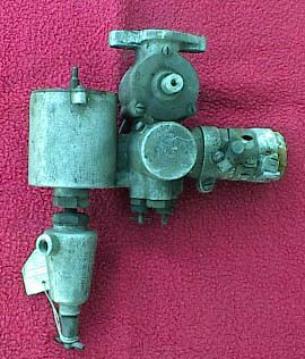

Kingston prototype 2-barrel for 1934 V-8. Side view. No known

production.

|

Kingston prototype 2-barrel for 1934 Ford V-8. Bottom view. No known

production.

|

Linkert

Linkert, original known as Langsenkamp-Linkert or L & L, carburetors

were manufactured in Indianapolis. Early products included replacement

service parts for Stromberg, Carter, and Ball & Ball carburetors. There

are links with Schebler, Hawk, and Sherman; but I am unsure of the links so

these may be left to the investigation of the reader. Early Linkert catalogs

show the Linkert model LD as replacing the Schebler model D, the models M and

MR which appear to be Schebler motorcycle carburetors. A model R undraft

universal, and a model DD downdraft universal are also listed. A cabinet is

pictured which is identical to the Hawk aftermarket cabinet in style,

lettering, font, everything except the name. The cabinet is pictured under

Hawk / Sherman. As far as I am aware, Linkert original equipment carburetors

were used only by Harley-Davidson

Marvel

Marvel is another one of the older carburetor companies. I have records of

Marvel carburetors for original equipment use from 1910~1939. Many early

Marvel carburetors used the Marvel Heat Control System, which basically

routed the air/fuel mixture through a tube inserted into a chamber which was

part of the exhaust system. A dash control provided the operator a method to

control the amount of heat. Buick was Marvel's largest customer, beginning in

1912, and exclusively from 1914~1933. In 1934, Buick added Stromberg as a

second carburetor vendor, but continued to use Marvels along with Stromberg

through 1938.

|

|

|

|

|

|

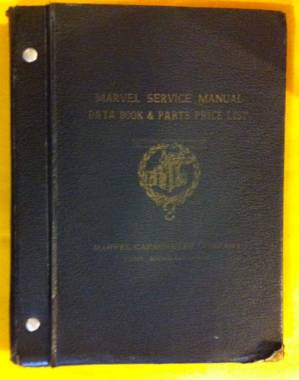

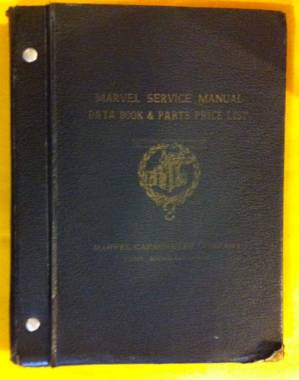

Marvel Sales & Service master book about 1930 back to 1916. Very

comprehensive.

|

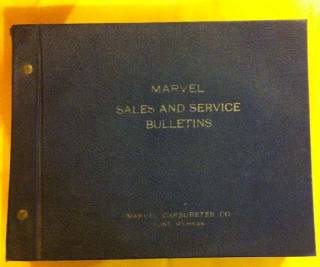

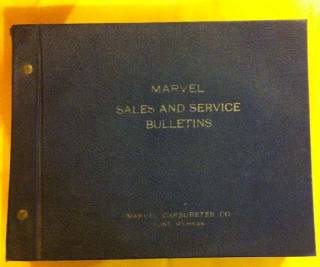

Exceptionally rare Marvel Sales & Service bulletins. Marvel issued

bulletins on a regular basis to update the Master book. In 50 years, have

seen only 2 of these

|

One of a number of different Marvel parts cabinets. These contained an

excellent selection of jets, fuel valves, air valve springs, and other parts

|

Marvel factory carburetor tool set. Only one I have ever seen.

|

|

|

|

|

|

|

Two views of two-barrel Marvel updraft number 10-1577

|

|

|

|

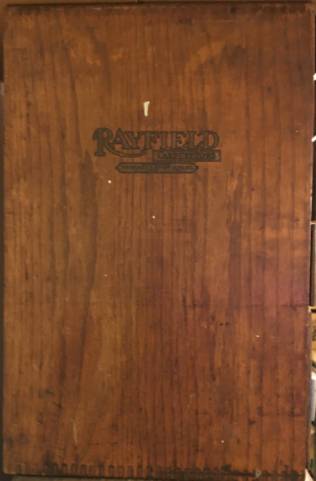

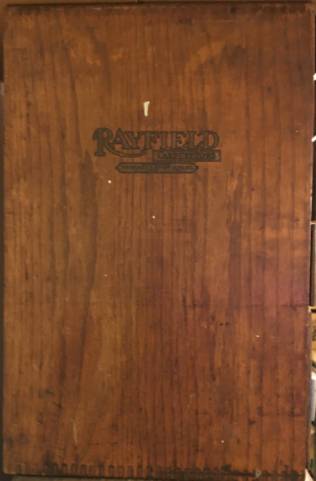

Rayfield

Rayfield carburetors were produced by the Findeisen & Kropf Company,

in Chicago. While Rayfield produced some exceptionally detailed manuals for

the industry, the manuals do NOT reference if the application is original or

aftermarket; thus it is difficult to research Rayfield applications. Our

records show applications from 1910 through 1927 for original equipment.

|

|

|

|

|

|

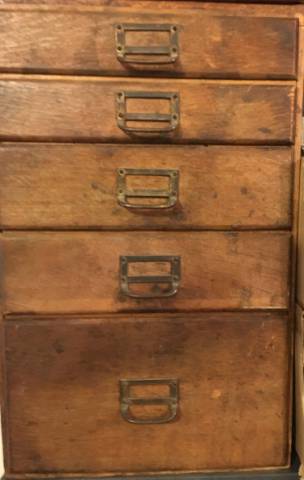

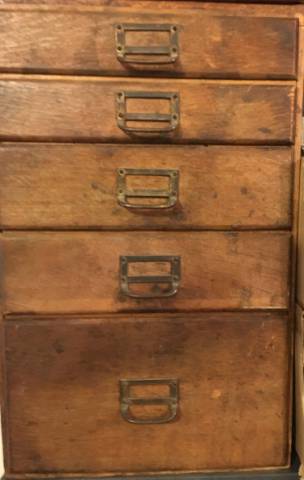

Two different views of a wooden Rayfield parts cabinet from circa 1915.

|

|

|

|

Rochester

Rochester Carburetor is a division of GM, and produced their first

carburetor, the type AA two-barrel, for Oldsmobile in 1949. This model

featured air intake from the back, thus lowering the total height of the

carburetor, and a gear driven accelerator pump. The type AA was discontinued

after two years of production. Rochester added a single-barrel carburetor in

1950, which was original equipment on the Chevrolet 6-cylinder for many

years. Rochester introduced the model BB two-barrel in 1951, but it survived

only a single year. In 1952, Rochester introduced the 4-Jet a.k.a. 4G a.k.a.

quadra-jet. The quadra-jet reference is not a mis-print, as the 4G series was

referred to as a quadra-jet in many Rochester documents. This has caused much

confusion among enthusiasts who know the quadra-jet as the 4M (spread-bore)

series introduced in 1965. The Rochester documentation refers to BOTH as

quadra-jets. Rochester introduced a two-barrel in the G series in 1955. The

2G, in addition to being a great home-to-market carburetor, was the backbone

of many factory multiple carburetor set-ups. The three two-barrel set-up was

introduced in 1957 by Oldsmobile on the J2 option; but made famous by Pontiac

as a "tripower". The 2G series lasted into the 1980's. In 1965,

Rochester introduced the 4M series, on the Chevrolet 396. The Quadrajet or

Q-Jet, was one of the most successful of all 4-barrel carburetors. Used

primarily by GM, Ford also used the carburetor in the early 1970's on their

429 CID.

|

|

|

|

|

|

Rochester 4-barrel carburetor known a "4-Jet", "4-G"

and "Quadri-jet". Note the position of the identification tag

|

Rochester 4-barrel carburetor known a "4-Jet", "4-G"

and "Quadri-jet". Note the position of the identification tag.

Note also the position of the stamped last four digits of the tag number,

in this case 7221 from 7007221 that is SOMETIMES present, even if the tag

is not present.

|

Rochester 4-MV a.k.a. Q-Jet, Quadrajet 7028273 (Pontiac Ram Air) note

the dust cover (boot) covering the accelerator pump shaft. The choke

pull-off is a replacement, as the originals were gray and black plastic,

rather than white plastic.

|

Two Rochester type 4-GC 4-barrel carburetors used on the 1955 Cadillac

El Dorado

|

|

|

|

|

|

|

Rochester type RC sidedraft carburetor, complete with alcohol control

valve, vacuum controls, and turbocharger that was factory equipment on the

Oldsmobile Jetfire

|

The infamous Rochester "flattop" type AA used on 1949 and 1950

Oldsmobiles, Rochester's first carburetor. Always troublesome, these carbs

were discontinued after 2 years. For current enthusiasts, the solution is

the Carter WGD which, while original, was used on only a few original

applications, so sometimes difficult to find. See the Carter section.

|

Internal troublesome "innovations" used on the Rochester AA.

The accelerator pump is a gear-driven diaphragm (center). Rochester put the

diaphragm in the rebuilding kits, but mechanics had difficulty getting the

gears synchronized, so then Rochester started selling the assembled pump in

its housing (left). The vacuum piston assembly housing is cast, rather than

stamped. To my knowledge never available in the aftermarket. The enthusiast

must disassemble, and then reuse the stem and spring with a new diaphragm.

|

The Rochester type BB replaced the type AA. Used for 1 year only, on

Oldsmobile and Cadillac, and then discontinued. Rochester discontinued

making 2-barrel carbs until 1955 when they introduced the 2G series, which

continued into the 1980's.

|

|

|

|

|

|

|

Sold aftermarket by Rochester:

"The CARB-AIRATOR automatically adds air to the engine manifold to

overcome the extra rich idle mixtures caused by excessive HEAT during

prolonged periods of hot engine idling"

|

|

|

|

Schebler

Originally known as the Wheeler-Schebler Carburetor Company for its two

founders, Frank Wheeler and George Schebler. The company started

approximately 1904, and continued through the early 1930's. While

Wheeler-Sehebler was the correct name, most refer to the carburetors as

Scheblers. Most Schebler models were single-barrels, but the company did sell

an updraft two-barrel called the S-duplex in the late 1920's and early

1930's.

|

|

|

|

|

|

Two views of the Schebler S-Duplex number SX-389 used on the J

Duesenberg

|

|

Schebler model O, used on the 1913 Buick model 25

|

|

Stromberg

Stromberg started selling carburetors in 1909. The carburetor was

originally known as the "Goldberg", the name of the chief engineer,

but changed to Stromberg very quickly. Strombergs with the Goldberg cover are

quite scarce. Stromberg sold carburetors through the 1974 model year. GMC

trucks, with their V-6, was Stromberg's last customer. When GMC changed to a

re-badged Chevrolet in 1975, Stromberg lost its last customer.

|

|

|

|

|

|

"Goldberg" extremely early Stromberg bowl cover

|

Difficult to see in the picture, but under the "Stromberg

Carburetors" is the line "Formerly known as the Goldberg"

|

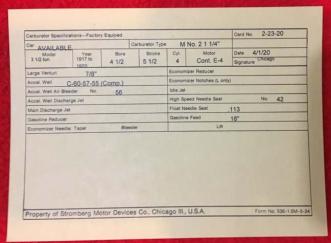

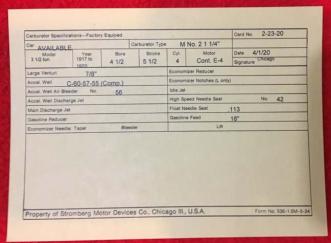

Wooden card file box from 1920. Stromberg issued "specification

cards" for each of their carburetors. There was a style of card for

original equipment carburetors, and another style for aftermarket

carburetors.

|

Sample specification card

|

|

|

|

|

|

|

Production Master - Stromberg type EE-7/8 number A-17690, known to the

hot rod world as the Stromberg 81. Production masters were the official

calibration for the specific applications. Occasional units would be pulled

from the assembly line, and the calibration compared to the production

masters.

|

Production Master - Stromberg type EE-1 number A-18271, known to the hot

rod world as the Stromberg 97. One of the most important, if not one of the

best, carburetors ever built. In the 1930's and 1940's, salvage yards were

full of Ford V-8's, and the Stromberg EE-1's were cheap. The hotrodders

that could not afford Winfields or the specialty Rileys, used the Stromberg

EE-1.

|

Bottom of the Stromberg prototype 3-barrel from the mid-1930's,

supposedly to be used in tandem on the Cadillac V-12 engines.

Unfortunately, Cadillac discontined the engine and continued the V-16.

|

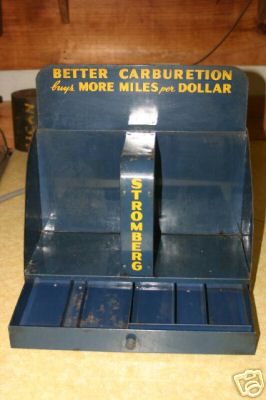

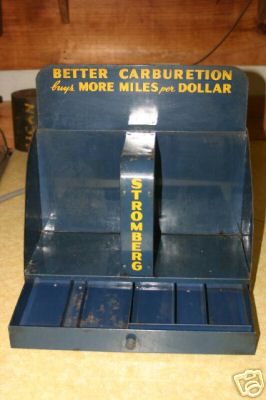

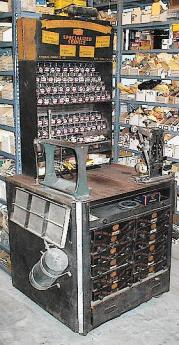

Stromberg counter-top display originally holding rebuilding kits and

gasket sets on top, with small parts (fuel valves, pumps, etc.) in the

drawer

|

|

|

|

|

|

|

Stromberg passenger and truck carburetor tool kit from 1930's. Note the

empty positions in the tray. Stromberg offered a more expensive kit using

the same box which also contained a set of reamers. Very few kits were sold

containing the reamers.

|

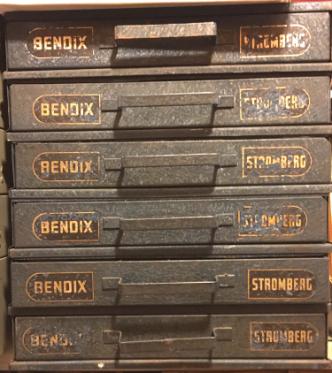

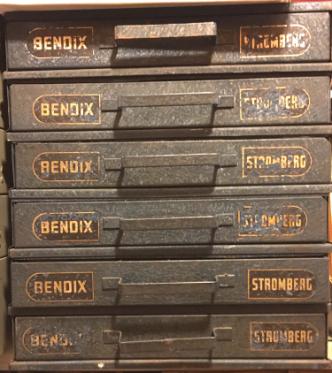

Early 1930's Stromberg metal parts cabinet. Drawers were stackable, and

could be added as necessary.

|

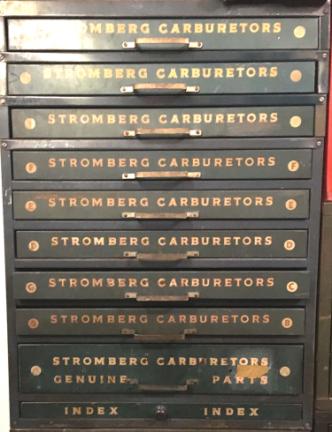

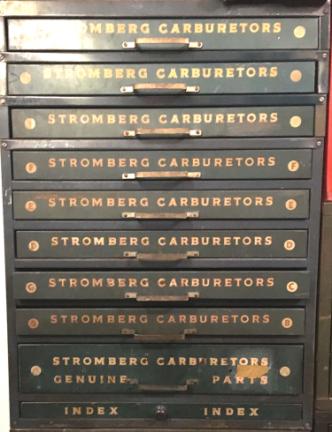

Late 1930's Stromberg metal parts cabinet, with parts index. Drawers

were stackable, and could be added as necessary.

|

|

Tillotson

Early Tillotson literature is scarce. The earliest verifiable application

for Tillotson is 1915. There may have been earlier applications unknown to

us. While early Tillotsons were used on cars, trucks, tractors, and marine

applications; by 1935, Tillotsons were mostly used on outboard marine

engines, with a very few tractor applications. A few heavy duty carbs were

produced for the military during WWII. Post WWII, Tillotson mostly

concentrated on small engine applications.

|

|

|

|

|

|

Tillotson cabinet. The glass bottles contain a variety of screws, jets,

fiber washers, springs, etc.

|

|

|

|

Winfield

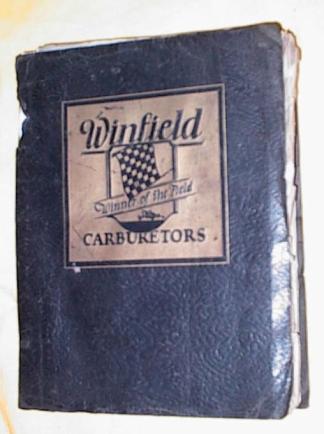

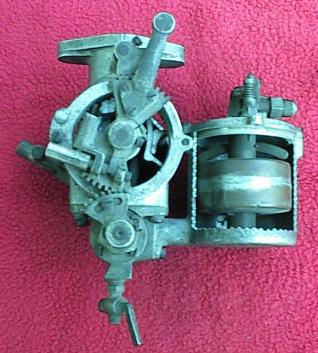

Winfield manufactured a rotary throttle carburetor for the aftermarket. I

have no record that the Winfield was used as original equipment on anything.

The Winfield caught on with the performance enthusiasts, perhaps because of

the Winfield (Ed Winfield was an extremely successful racing driver) name.

|

|

|

|

|

|

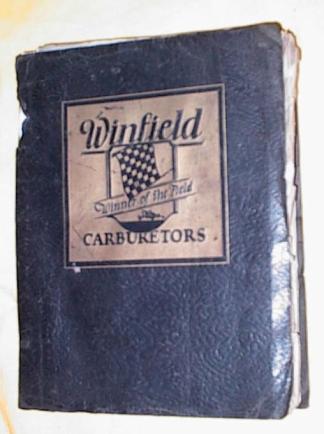

Winfield factory master catalog

|

|

|

|

Zenith

Zenith-USA is one of the older carburetor companies, that still survives

today. Early Zenith literature is scarce, and the earliest confirmed

application in my database is 1912. Zenith produced carburetors for cars,

trucks, industrial, agricultural, marine, small engine, and aircraft

applications. Zenith also produced tools, cabinets, and other related

carburetor products.

|

|

|

|

|

|

Zenith mileage tester. Metered a small measured amount of gasoline. This

could be attached directly to a carburetor, bypassing the fuel pump, to

determine mileage.

|

|

|

|

Lesser known

carburetor brands

|

|

|

|

|

|

Duff Engineering patent cutaway. There is no evidence this unit made it

past the prototype stage. Note the rotary throttle which is gear driven.

|

The Fish M-1 carburetor. Will say no more!

|

The "Pogue" carburetor, manufactured by the "Winnipeg

Carburetor Company". The original ultra high mileage carburetor. In

more than 60 years of working on carburetors, have yet to speak to anyone

that had one on a running engine.

|

The Woodworth "VCCV" vacuum controlled constant velocity

carburetor. Also associated with Kendig, and the forerunner of the

Preditor.

|

|

|

|

|

|

|

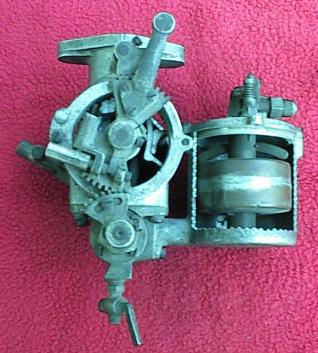

Juhacz rotary throttle carburetor. A number of carburetor companies

tried to make a rotary throttle carburetor work. All of which I am aware

had part throttle and acceleration issues. Winfield was by far the most

successful, as it was used primarily for racing (wide open throttle).

|

Master rotary throttle carburetor. The only rotary throttle carburetor

that I am aware of with an original equipment application. Both Austin and

Owen-Magnetic tried a Master on factory race cars in 1915.

|

Mallory, of ignition systems fame, offered an aftermarket single barrel

carburetor in the 1930's for Chevrolet, Ford, and Plymouth 6 cylinder

engines.

|

The Penberthy Ball & Ball type DV (double venturi). If one visits

several of the various automotive forums on the internet, one will

doubtless find a reference to the first 4-barrel carburetor used by the

1918 Oldsmobile. The Penberthy Ball & Ball carburetor, like MANY other

makes, used auxiliary air valves. Somehow some enthusiasts have determined

that 2 barrels plus 2 auxiliary air valves add up to 4 barrels? even though

Penberthy advertised the carburetor in 1918 as being a double venturi.

|

|

|

|

|

|

The Riley carburetor. A pair of these on a Ford A were the hot set-up

for those who could afford them.

|

The Flynn, which to my understanding, was a later extension of the

Riley.

|

In the early days of motoring in the USA, one of the most popular cars

was the Ford Model T. As were so many T's in comparison to other vehicles,

the aftermarket manufacturers concentrated on accessories and

"improvements" for the Model T. In fact, because of the vastness

of this market, a new phrase was born:

"fits to a T". The Sunderman Carburetor Company offered a

replacement, which had a trap-door similar to the design of some early

mouse-traps. While early advertisements do not show the "Mouse

Trap" data plate, at some time the name was given to this carburetor.

|

Ballwin-Washington

Ballwin-Washington was a company that produced a large selection of

carburetor parts for the carburetor rebuilding market. There are links to

Hawk, Sherman, Pacco, and Ace Electric as to the ownership of

Ballwin-Washington. They produced some very elaborate catalogs to market

their carburetor parts.

D & G

Valve

|

|

|

D & G Valve

sold an aftermarket fuel valve using 2 balls rather than the conventional

pointed valve

|

Hawk / Sherman

Hawk and Sherman, like Ballwin-Washington, were suppliers of carburetor

parts to the carburetor rebuilding industry. Additionally, Hawk offered a

retail cabinet of a vast selection of carburetor parts.

|

|

|

|

|

|

The Hawk retail cabinet and contents

|

|

|

|

Hygrade

Hygrade was probably the best well-known, and had the widest selection of

aftermarket carburetor parts beginning in the 1930's. In addition to

carburetor parts, Hygrade offered tool sets, retail cabinets, retail

rebuilding work stations, and some fabulous cataloging.

|

|

|

|

|

|

Two views of the Hygrade float adjustment gauge for updraft carburetors.

The fitting was screwed into the bowl drain hole in the carburetor, and the

fuel level in the bowl would be displayed in the glass tube. The technician

could take measurements, then remove the bowl cover and fuel valve and make

adjustments.

|

|

Hygrade aftermarket brass float for early Marvel carburetors, replacing

the troublesome cork float.

|

|

|

|

|

|

|

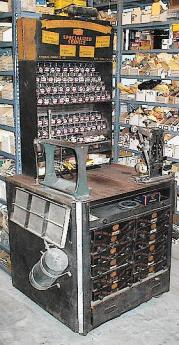

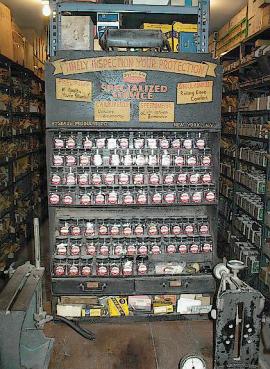

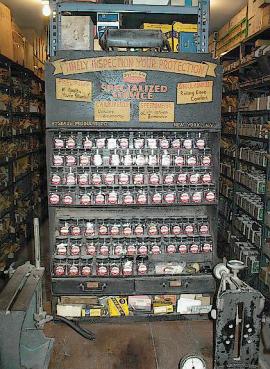

|

Three views of the Hygrade Specialized Service workstation. The work area is appoximately 32 inches tall.

The entire workstation is more than 6 feet tall. There is a foldable parts

tray on each side, a pedestal where carburetors may be mounted, a tank for

either air pressure or vacuum, and a fuel pump tester (on the right). The

first drawer under the work area contains a number of special tools

produced by Hygrade. The rest of the drawers are full of carburetor, fuel

pump and speedometer rebuilding parts, as are the glass jars.

|

|

|

|

Parker

Brothers

|

|

|

Parker Brothers marketed an aftermarket fuel valve which featured an

aluminum plunger (non-magnetic) with an embedded neoprene disc that sealed

against and inverted flare fitting. This was called the "Master Float

Valve".

|

Vernay

The Vernay Corporation produced fuel valves (a.k.a. needle and seat

assemblies) with the neopreme tip for carburetors. As their market was

wholesale only, to the carburetor companies, and the aftermarket repair kit

companies, memorabilia is scarce. However, they did produce an interesting paperweight.

This is a transparent plastic cube of 2 1/2 inches.

|